Home / The Project

The Project

Objectives and Ambition

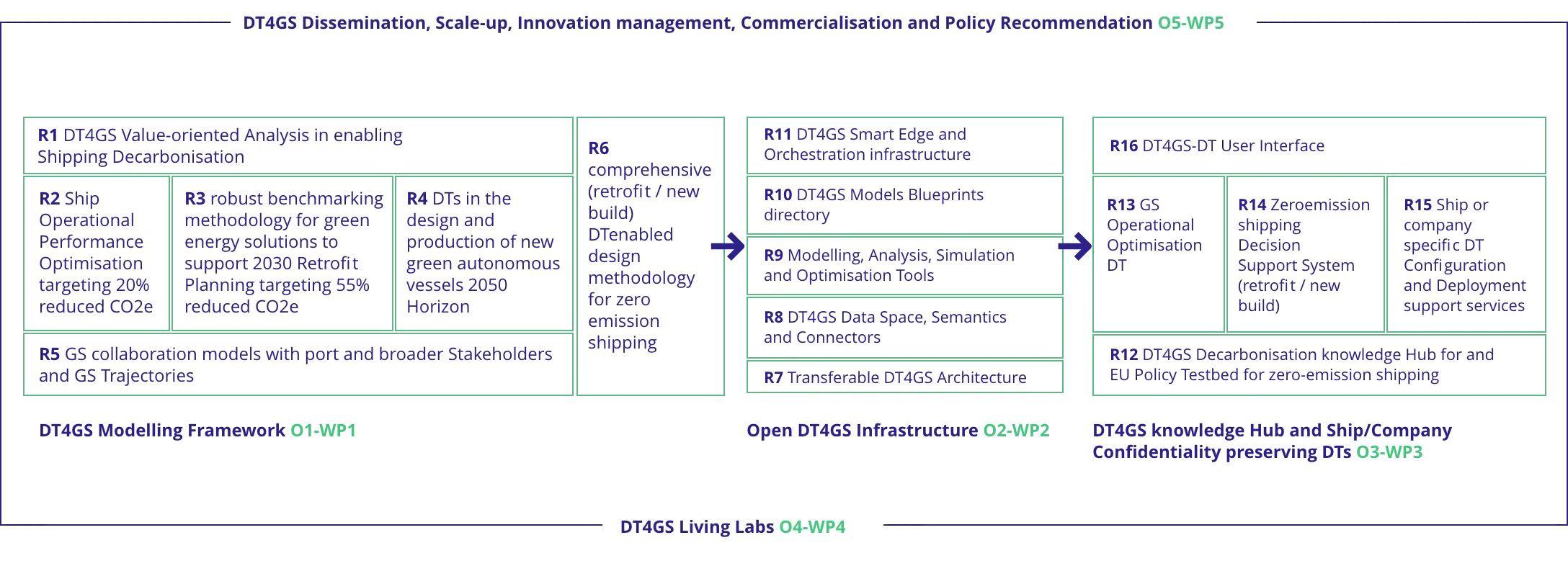

The project objectives, results, verification means are presented in the following sections

R1. Value-oriented analysis guiding the specification of high-level requirements for the project’s research and development activities including a) Relevant scenarios and strategic case studies; b) classification/regulatory issues; c) alignment of industry stakeholders with key GHG reduction strategies and solutions; d) key transitioning challenges and enabling factors, and d) policy and standardization roadmaps.

R2. Analysis, aggregation, and standardization of data-driven ship performance optimization models to support supervisory control and optimization of environmental performance [TRL2-3→5]

R3. Creation of robust benchmarking criteria and methodology to instrument and manage environmental impact and to compare and select optimal green energy solutions [TRL4→5] and associated models, to drive model/solution deployments commensurate with suitability and maturity assessments [TRL4→5-6].

R4. Formal methodology for applying Digital Twins in the design and production of new green autonomous vessels. This includes the aspects of sensing, monitoring/measurement and control within the ship, as well introducing intelligence into the shipbuilding process [TRL4→5-6].

R5. Model development for the collaboration between ships and port green fuel bunkering services and port DTs for end-to-end supply chain optimisation [TRL4→5-6].

R6. Development of comprehensive (retrofit/new build) DT-enabled design methodologies for zero emission shipping and to manage continuous and sustainable transitions for the project’s LLs by integrating the new methods and models proposed in the project, R2-R5, based on relevant concept design work. A focus on the definition of KPIs orienting the design choices and manufacturing processes [TRL3-4→5-6].

R7. High-level requirements and technical specification; Transferable DT4GS Architecture, aligned with shipping industry standards and including an open DT4GS data schema, based on R1, R2 and R6.

R8. Specification and implementation of the DT4GS infrastructure to represent, manage, and communicate data, comprising: a) an automated Trust and Identity Management Framework; b) a service producing Analysis-Ready Ship Data (ARSD) generated either statically ahead of time or dynamically at query time; c) a semantic broker to pool relevant data from several sources; d) the shared sectoral DT4GS Dataspace; and e) the necessary internal and external connectors to facilitating management and exchange of data. [TRL2-5→5-6]

R9. Development of the environment for DT-based modeling and simulations, provision of necessary storage and processing for the DT4GS AI tools and Data Analytics. [TRL3-4→5-6]

R10. Specification of model blueprints, creation of quantum analogues for AI/ML and optimization models, and services enabling periodic refinement based on operational feedback of the Open Model Library [TRL3-4→5]

R11. Support service provision and execution via suitable Edge and Orchestration infrastructure and connectors, in turn enabling automated configuration of ship models and adaptive self-learning [TRL3→5-6]

R12. Creation of a hub to monitor data on shipping emissions and the performance of Green Shipping (GS) solutions. This utilises the outputs of the LLs, and other data sources from knowledge networks organised in WP1 including benchmarking against other industry sectors; it will provide a key data source for updating DT4GS Solutions and will support an EU Policy Testbed for zero-emission shipping [TRL3-5→5].

R13. Creation of a reference DT for low-emission ship operations optimisation according to the specifications of [R1] and models [R2,10] and WP2 components [TRL3-4→5-7].

R14. Creation of a zero-emission shipping Decision Support System implementing R5 and supporting investment decisions towards improvements in energy efficiency and reduced emissions resulting from incorporating decarbonisation innovations for both new designs and planned retrofitting, including:

a. A reference DT to support decarbonisation-related ship retrofitting designs and decisions according to the models/specifications of [R3] [TRL3→5-6].

b. Creation of a planner tool to support decisions concerning long-term investment decisions for new zero emission ship design, construction, and operation [R3] [TRL3→5-7].

R15. Specification of a methodology and support services for shipping companies to use the tools from WP2 in a simple way so that the creation and deployment of DTs can be as automated as possible [TRL3→5].

R16. Define the framework with which to evaluate the LL outcomes’ coordinate LL activities and perform a comprehensive impact assessment of the benefits to all 4 Living Labs.

R17. LL1 Baleària ROPAX centric DT.

R18. LL2 DANAOS Container centric DT.

R19. LL3 EURONAV Tanker centric.

R20. DT; LL4 STARBULK Bulk centric DT.

R21. LL5 Extended industry LL from month 16.

R22. Dissemination of key outcomes through relevant media and communication packages, networking with other past and current EC-funded projects and liaison activities.

R23. The DT4GS stakeholders’ Cluster with advisory and user groups will be formed to include operators and authorities from all shipping segments across the EU’s geographic areas.

R24. Provide IP Management and IP Protection (Patent Filings protecting commercial advantages for the EU shipping sector) and DT4GS market sector analysis, business modeling and strategy for commercialization.

R25. Capacity building from the project results and outputs including Training Workshops and a comprehensive sectoral DT4GS Guide with steps to move from planning, implementation, replication and scale-up linked with awareness, results communication, feedback and education transferability activities for EU’s shipping actors.

R26. Policy recommendations on DT scale-up in the shipping and ports community.

Going beyond

DT4GS has set the ambitious target of playing a key role in the realisation of the potential benefits of DTs towards zero-emission shipping. To achieve this, the project will build on previous results, will capitalise on cooperation opportunities with ongoing projects and initiatives and will go beyond the state of the art in a number of ways, as described below.

The project provides a next-generation solution for total ship operational optimization based on DT technology capable of automated adaptation according to ship/vessel types and operational profiles, to incentivize investments towards full decarbonization. This will utilize the DT4GS (Green Shipping) Dataspace as part of the Open DT4GS infrastructure for robust data collection, transmission, analysis, simulation and optimization to enable operational and energy efficiency improvements for decarbonization and emissions reduction. Furthermore, it will support condition-based ship surveys and operations which are remote and more automated. Our planned use of fog/edge computing technology will provide latency and security benefits and added levels of intelligence, orchestration and autonomy in ships. More specifically, advancements, largely building on assets available through the project’s partners include:

(1) DT auto-adapting capabilities for ship/vessel class and associated vessel operational profiles;

(2) robotic data acquisition with 3D reconstruction;

(3) a novel automated and distributed Trust and Identity Management Framework enforcing the NIS directive, GDPR and Cybersecurity acts;

(4) automated and instrumented analysis-ready ship data generated by events or dynamically at query time;

(5) development of DT blueprints for ship operational performance optimization and creation of quantum analogues for AI/ML and optimization models, targeting increased accuracy, standardization, and reusability;

(6) intelligent monitoring and control connectors (IMCCs);

(7) the DT4GS (Green Shipping) Dataspace wirh innovation across data value, interoperability, trust and governance and new IMCCs particularly to support automated configuration of DT Edge components in ships using quantum models;

(8) control points business logic for automated configuration and updating of ship models;

(9) integration of advanced 5G capabilities.

DT4GS delivers a Virtual Testbed and Decision Support System, embedding a zero-emission shipping methodology, and built on top of the DT4GS Dataspace to enable different stakeholder communities to iteratively search through alternative technologies and compose optimized designs helping realize the 2030 55% CO2e reduction and longer term zero emission shipping. This is achieved through the:

(1) Establishment of a Decarbonization Knowledge Hub linked to knowledge networks for key features of the ship, energy and ICT domains. Collection, aggregation, processing, dissemination and exploitation of existing knowledge supported by roadmaps for addressing existing gaps in knowledge and technology;

(2) Provision of a taxonomy of green shipping technologies and a robust assessment/benchmarking method taking into account the quality, reliability and timeliness of the evidence that supports the decision-making process;

(3) Data-driven Green Ship 2050 reference models per ship type, by employing blueprints for specific ship/vessel types, taking into account size and other parameters, exploiting synergies between emerging ship and energy innovations, and new production methods;

(4) A zero emissions shipping Virtual Testbed for the sector which will enable:

(i) Shipping companies to explore the impact of alternative decarbonization options, (ii) Equipment manufacturers to upload models of their equipment to test performance under alternative configurations; (iii) Policy Makers to continuously analyze the state of the art, assess policies for zero-emission shipping. (5) Modeling digital transformation procedures and organizational processes (including governance and security s) to support adoption of DTs;

The reluctance of the shipping sector to embrace digitalisation in general, is also reflected into a conservative posture towards the adoption of DTs. Lack of hard evidence on DT value, combined with data sharing mistrust, are important issues that remain unaddressed. DT4GS addresses this head-on, by establishing a SC-centred innovation ecosystem, for the co-creation, collective experimentation and evaluation of innovative ideas, scenarios, concepts and related technological artifacts in real life use cases. Such user driven DTs operational in 4 ships by month 16 will enable the consortium to build a strong DT4GS Cluster and will give DANAOS, and SEASTEMA powerful value propositions as market leaders in shipping digitalization.

An important challenge with regard to designing effective DTs lies not only in meeting shipping’s goals, but also in achieving a more holistic perspective, which incorporates the evolution of critical adjacent areas. This link between shipping, green energy production, storage, and distribution technologies, compatible with real-world operations, green mobility technologies, and environmental and social considerations, is currently missing. DT4GS goes beyond the state-of-the-art by combining models from the shipping and transport domain with models from green fuels and green energy production, distribution, and optimization. This ensures both the achievement of synergies and also the parallel evolution of DTs in line with developments in the shipping and energy domains and future integrated autonomous mobility systems.

DT implementations so far have been focused on distinct areas such as machinery, hull, energy or port call optimisation. This has significant shortcomings, spanning from the business level (i.e. inability to capture the added value and efficiencies that integrated DTs can bring), down to the implementation level (i.e. data fragmentation and interoperability barriers). DT4GS goes beyond the state of the art, by integrating all these functionalities and linking to specific implementation horizons (see Figure 1–6) to guide adopters in their usage and achieve a strong impact on the collective capability of the waterborne industry to harmonize efforts and increase synergies between DT applications in shipyards, equipment manufacturers, class societies, ports, and policy makers.

Impact

Product lifecycle management (PLM) solutions offer a holistic approach to shipbuilding and a single source of service knowledge that increases accuracy and coordination across the global service network, enabling fleet upgrades, improvements, and modifications that are crucial to overall fleet performance. Such benefits have established a digital shipyard market expected to reach USD 3,967 million by 2030, from an estimated USD 693 million in 2020.

Hyundai Heavy Industries, one of the world’s largest shipbuilding companies, installed the first PLM infrastructure that has delivered enhanced productivity and high design quality incentivizing similar applications in many EU sites.

Artificial Intelligence (AI) is increasingly used to enhancement automation of design, and production and deliver increased automation in ships. Pairing technologies include loT, blockchain, big data, robotic process automation with Al and ML. Big data analytics helps to uncover hidden patterns, in market trends, and in real-time risk assessments.

Importantly, DTs provide the ability to instantaneously analyze, compare, and integrate data such as ship IoT monitoring, port state control inspections, events history terminal feedback to identify anomalies and trends.

Even though DT Product lifecycle management offers a way to long-term decarbonization in shipping, the medium-term impact is likely to be small, as world fleet renewal is at slow process. For the next 20 years, the efforts of decarbonization will primarily require investments from ship owners/operators in CO2e reducing solutions. Consequently, the target impact for DT4GS is to enable shipping companies capitalize on the DT potential to increase ship efficiencies to constantly reduce CO2e in the short-term, and to support robust investment decisions and planning [retrofit/new builds] in the longer term.

1

A next-generation user led solution for total ship operational optimisation based on DT technology capable of adaptation according to ship type and increasing ship automation, thus delivering superior cost effectiveness to ship operators.

2

A Virtual Testbed and Decision Support System, creating a collective capability of the waterborne industry to harmonize efforts and increase synergies between DT applications in shipping companies, shipyards, equipment manufacturers, class societies, ports, and policy makers.

3

The DT4GS Decarbonization knowledge Hub which will provide a trusted observatory of key decarbonization solutions.

Project’s Pathways Towards Impact

The results of the project will contribute to the acceleration of green shipping transformation targets in the short, medium term and long-term as follows:

i1

20% reduction CO2e in the short term by use of DT4GS for fleet performance optimisation to be promoted for the widest possibly industry use (by launching both commercially backed and open source-based services) creating a launchpad for accelerated progress towards zero emission shipping.

i2

20% improvement cost efficiency for GS solutions using DT4GS for reducing the cost of physical testing in the short to medium term (support services for equipment manufacturer’s, retrofitting designers and yards, and class).

i3

55% reduction CO2e by 2030 using DT4GS for robust planning and progressive retrofitting of GS technologies whilst capitalizing on the benefits from i1 and i2 to introduce incremental automation of ship functions.

i4

Zero-emission waterborne transportation by 2050 by use of DT4GS to support new ship design and construction with integrated GS technologies/systems. Target faster DT adoption by a broader range of ship designers and shipyards including SMEs with opensource options.

Expected impact towards topic outcomes

The DT4GS value proposition is a user-oriented, trusted Open Digital Twin Framework that is used to deliver the following outcomes.

Adoption of DT4GS for ship/fleet performance optimization by more than 20 shipping companies

Use of DT4GS zero-emission shipping Virtual Testbed and Decision Support System (retrofit / new build) by growing Cluster of shipping companies, shipyards and GS solution providers

Use of DT4GS services to reduce the cost of physical testing of GS solutions

DT4GS will support shipping companies in deriving zero emissions shipping transition plans for their fleets with increased confidence in techno-economic predictions and access to DT4GS zero-emission shipping Virtual Testbed and Decision Support System.

The shipping company partners will spearhead this activity, imparting their experience having already embarked in establishing decarbonization plans. The DT4GS decarbonization strategy will advance the interests of each stakeholder group, through quantifiable outputs from the LL’s plus will provide a “least-risk, best-reward” roadmap that best aligns to the macro-level business imperatives for each stakeholder group. A comprehensive capacity building, dissemination and communication strategy will ensure that DT4GS outputs are adopted and embedded across all shipping stakeholders.

Success in DT4GS will contribute to achieving European leadership in green technologies. The project guarantees a close interaction between research institutions, industry and high-profile SMEs. All partners, particularly SMEs and scientific staff, will gain novel technological know-how, establishing them as lead future actors in combining digital and greening sustainable technologies.

Living Labs

The overarching goal is to maximize sustainable adoption of the DT4GS innovations and energy efficient behaviors across the fleets of the four participating Shipping Companies (SC). DT4GS is designed as a SC-centred innovation ecosystem, for the systematic exploration, experimentation and evaluation of innovative ideas, scenarios, concepts and related technological artifacts in real life use cases involving SCs as co-creators of emerging ideas, and a real-world shipping DT deployment at sufficient scale to demonstrate implementation.

LL1

Company

Euronav NV

Fleet

74 vessels (mix of VLCCs, Suezmaxes, ULCCs and FSOs)

Status of decarbonization planning

Euronav has reached a reduction of 33% in Co2 emissions per ship between years 2017 – 2020. Moreover, as a Poseidon Principles signatory, Euronav is committed to (and achieved) at least 2% better performance vs. PP trajectory which foresees a consistent reduction of carbon emissions in a YoY basis

Use of vessel/fleet monitoring systems

Propulsion Analytics QUAD™, CMB FPM ™, Propulsion Analytics Hyper Cube ™, Euronav FAST ™ platform

The vessel to participate in project

Type: Crude Oil Carrier

Operational environment(s) Global

Energy demand

163 GWh/yr

Projected savings via DT

15%

LL2

Company

Danaos Shipping Co

Fleet

65/71 Container Vessels ranging from 2,200 TEU to 13,100 TEU

Status of decarbonization planning

Danaos meets IMO 2030 carbon intensity targets 11 years ahead, by achieving 41.5 % reduction in CO2e emissions per ton-miles for year 2019 compared with 2008

Use of vessel/fleet monitoring systems

LAROS (Prisma), CASSANDRA (DeepSea), WAVES (Danaos Management Consultants)

The vessel to participate in project

Type: Container

Energy demand

48 MW/yr

Projected savings via DT

> 20%

LL3

Company

Baleària

Fleet

30 ROPAX vessels

Status of decarbonization planning

50% CO2e reduction by 2030 (DT4GS goal for retrofitting solutions)

Use of vessel/fleet monitoring systems

Sensors and equipment for real time monitoring operation, energy consumption and emissions generated by 5 vessels – Green C Ports CEF EU co-funded project

The vessel to participate in project

Type: ROPAX

Operational environment(s) Short-sea shipping

Energy demand

155 GWh/yr

Projected savings via DT

> 20%

LL4

Company

Star Bulk Shipmanagement Company (Cyprus) Limited

Fleet

128 Bulk Carriers Ranging From 52,000 to 210,000 DWT

Status of decarbonization planning

Working with various stakeholders in many projects to explore the best solutions fit to our vessels and operation profile.

Use of vessel/fleet monitoring systems

Data acquisition hardware that feeds our own developed VPM software.

The vessel to participate in project

Type: Bulk Carrier

Operational environment(s): Worldwide

Energy

demand

Average power ≈50% MCR daily basis 365 days

Projected

savings via DT

As much as possible

but >15%